What is Car Wraps Made Of ? Here Are Some Good Options for Clear Car Wraps

In the market, various terms describe clear car wraps (PPF) materials, like TPH and TPU. As PPF car wraps gains popularity, people grow more informed. TPU PFF, seen as high-quality, with Argotec representing premium TPU. Utilizing imported aliphatic TPU substrates, Argotec positions itself as high-end. How can one determine a PPF product’s quality?

Why do PPF stress substrate quality? What makes a good substrate vital for PPF?

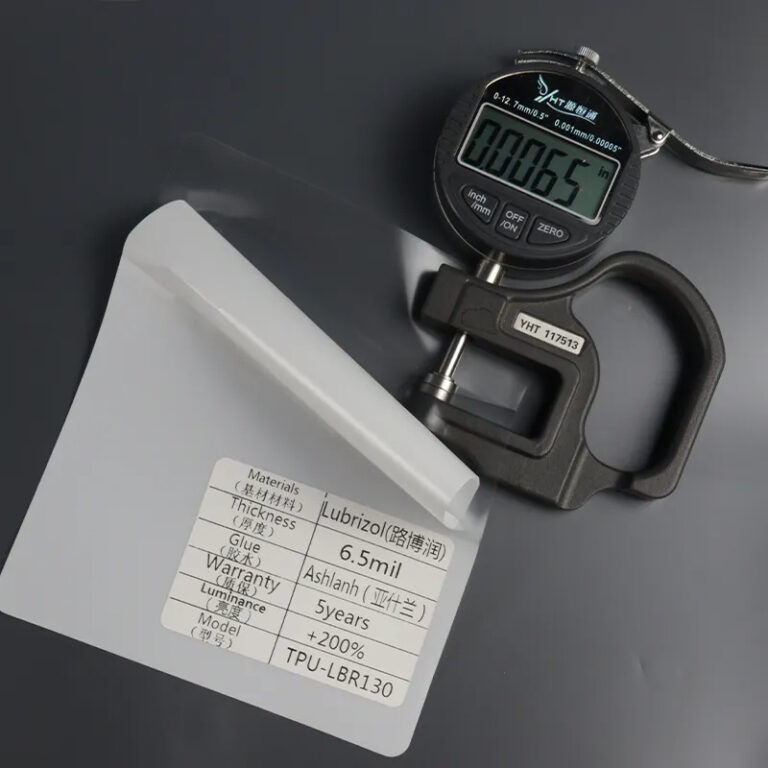

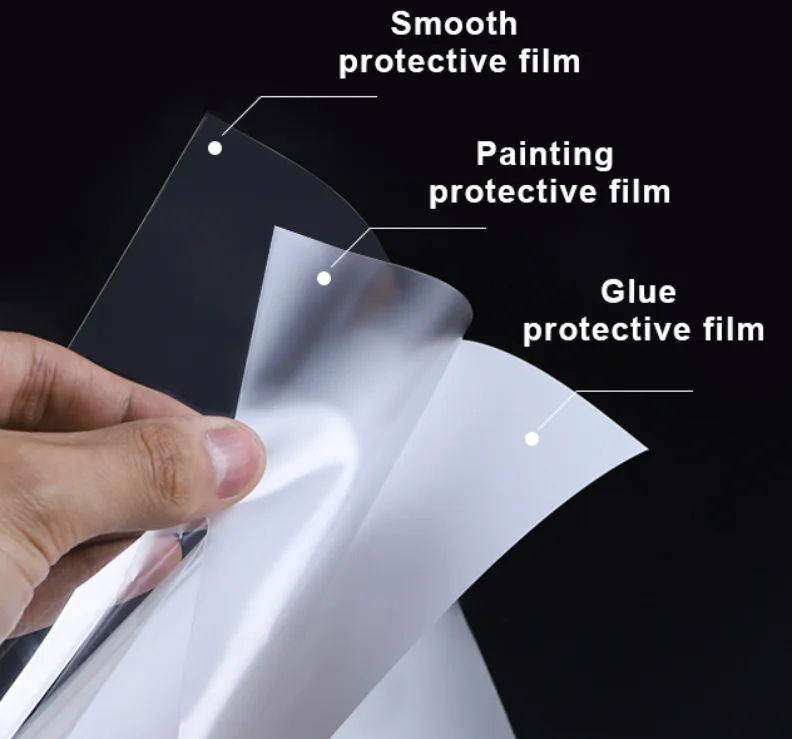

PPF consists of three main components: the substrate, adhesive layer, and coating, as illustrated below:

Adhesive impacts adhesion, potential paint damage, bubbling, and yellowing. Coating affects water repellency, corrosion resistance, durability, and external element intrusion.

Substrate is pivotal for scratch resistance, friction tolerance, and yellowing prevention.

Thus, competition in PPF quality centers on substrate excellence. Simplified: if a PPF has ten levels of scratch resistance, the substrate provides nine levels of protection, and the remaining level comes from the coating.

What makes Argotec substrate for paint protection film (PPF) stand out?

Established in 1988, Argotec is a globally renowned supplier of thermoplastic polyurethane (TPU) films. Acquired by SWM International in 2015, it integrated with two other film producers to supply TPU for various sectors including agriculture, healthcare, electronics, aerospace, and defense. Argotec specializes in specialty TPU film business.

For further details, please visit the website: https://argotec.com/

What makes Argotec's substrate for invisible car wraps so outstanding?

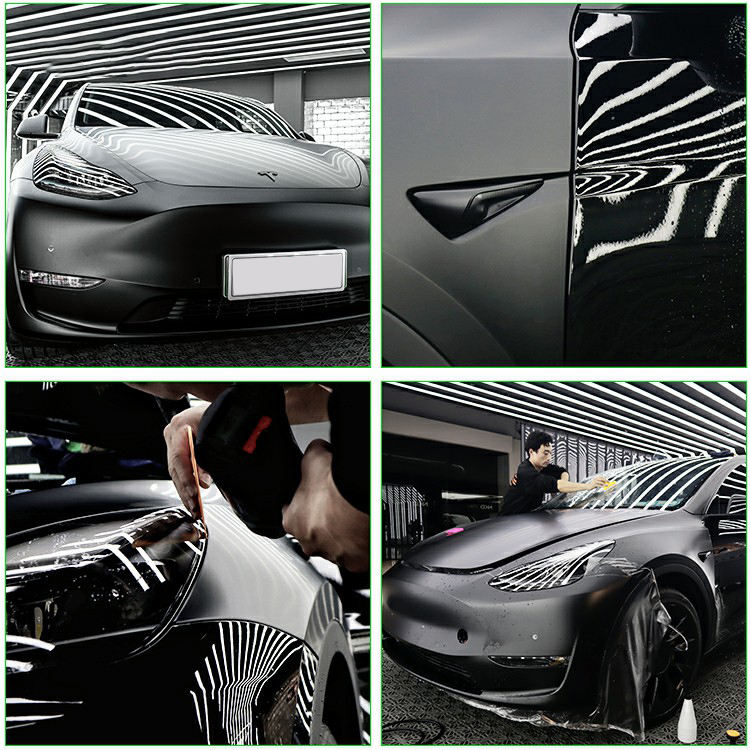

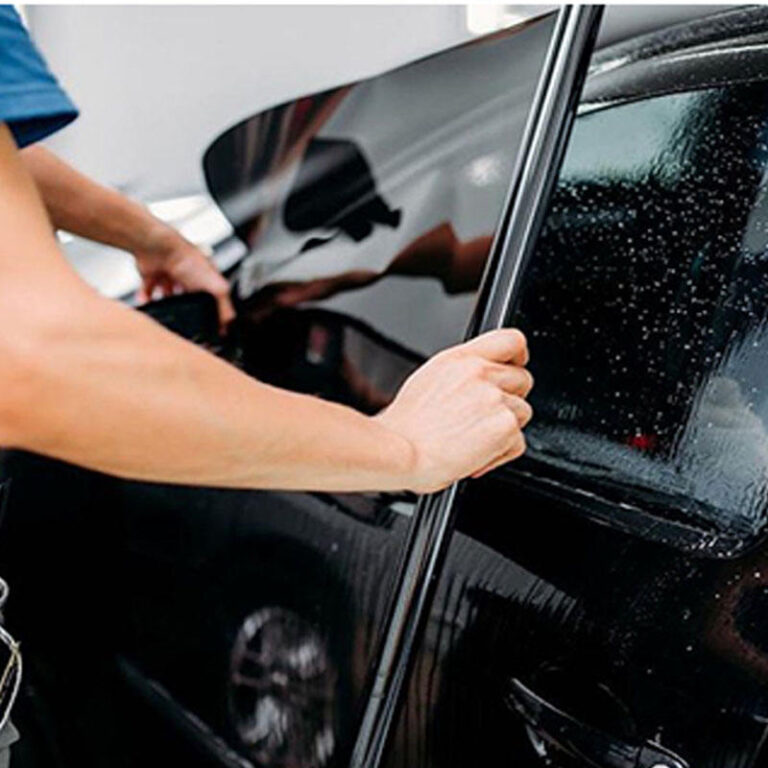

Let’s delve into the production process of invisible car wraps:

Step 1: Extraction of TPU Raw Material from Petroleum

Yes, the miraculous existence of invisible car wraps begins with extracting it from petroleum, initially in the form of transparent granules resembling rice. Argotec TPU, widely utilized in fields such as aircraft, armored vehicles, banking, and construction.

Step 2: Extrusion Molding of TPU Film

This step is crucial, as the extrusion technique involved is quite complex and currently only mastered by a handful of enterprises. The technology employed and its variations significantly influence the grade of TPU film produced.

Why is that? To simplify, consider polyurethane granules akin to flour in bread making. Producing quality bread (original film) requires precise additives to optimize various properties. Factors like selection and classification of polyurethane granules and additives, grinding process, cleanliness, etc., all impact the final film quality, including optical properties, abrasion resistance, thinness, elasticity, and tear resistance.

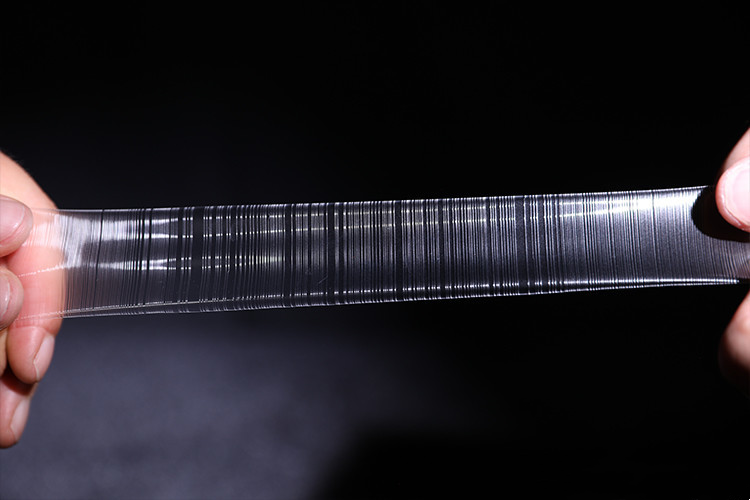

As depicted in the illustration below, differences in TPU raw films produced by different manufacturers are evident under magnification by specialized instruments. This disparity not only concerns the smoothness of the film surface but also compromises the tight structure and tensile properties of the original film.

Step 3: Coating & Adhesive Layers

This step involves the composite production of coating and adhesive layers onto the TPU original film through specialized processes (which may vary across different manufacturers).

Argotec, positioned within the invisible car wrap production line, dominates a crucial stage: film extrusion. Established in 1988, Argotec is a key player in this field, daring to claim the top spot where no one else dares. In the realm of high-end TPU invisible car wraps, Argotec virtually monopolizes 95% of the market supply share.

There are two identification methods here.

-

UV Light Exposure Test: Argotec’s aliphatic TPU exhibits no color changes after 1500 hours of UV exposure, while aromatic TPU and aromatic TPU with UV stabilizers experience significant changes after 1000 hours, with yellowing levels exceeding 40. Even after 1500 hours, Argotec’s aliphatic TPU remains below 10 on the yellowing scale.

-

Performance Testing: UV light exposure testing is the most direct method, but it’s generally inaccessible to most car enthusiasts due to testing conditions. However, we can discern differences between these two substrates based on their inherent characteristics and resulting properties.

Upon magnification, it’s evident that aliphatic TPU has a much higher density than aromatic TPU. This determines that during the coating and adhesive process, aliphatic TPU forms denser and more secure contact points with the coating and adhesive layers. Therefore, by subjecting invisible car wraps to equal-strength stretching, one can observe the size of fracture gaps. Products with smaller gaps undoubtedly represent superior quality. This is the simplest and most direct method!